Safety and Research go hand in hand. Every paper published from UChicago includes experiments that have been carefully designed to target scientific questions in a sustainable and safe manner. In our new Safety Spotlight series, the UChicago Joint Research Safety Initiative (JRSI) recognizes the deep thinking and field-specific knowledge behind the big results discovered by scientific leaders at our University. Highlighting this behind-the-scenes safety expertise provides a starting point for students and others to incorporate a safety mindset into their research.

Introduction

In their recent publication in J. Phys. Chem. C, Rebecca (Becca) Thompson, Michelle Brann, and Professor Steve Sibener investigated the adsorption of methane onto icy surfaces, an uncertain yet crucial event for reactions that lead to the formation of complex organic molecules in astrophysical environments — such as on comets, in planetary rings, and on outer solar system bodies like Titan.[1] Using a custom lab-built instrument, they explored how the sticking probability of methane to icy surfaces changes with the ice’s structure—knowledge critical to modeling atmospheric and astrophysical processes. “This is the first study looking at sticking probability across a wide range of ices” says Becca. To quantify the sticking probability, a molecular beam of methane with varying incident energies was aimed at an icy surface and the quantity of reflected methane was measured. At low methane incident energies, they found very similar sticking probabilities across the ice morphologies. However, as they increased the incident energy of methane, they found that the amorphous ice structures with pores maintained a higher sticking probability than the other structures. To their surprise, the sticking probability did not appear to vary significantly with pore size or orientation. They proposed that the increased sticking probability of methane to porous ices is a result of energy dissipation due to collisions between methane molecules and the pores. Bringing these fundamental results back to the scope of accurate astrophysical models, Becca points out that “this study shows that if we don’t have an accurate understanding of what the morphology looks like, then our estimates of gaseous uptake could be incorrect.”

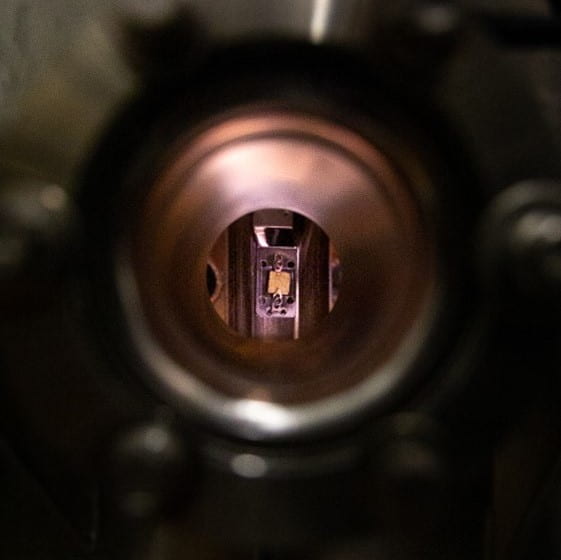

The Au(III) substrate on which ice films were grown within the ultra-high vacuum set-up can be observed through a porthole on the instrument.

Instrument design

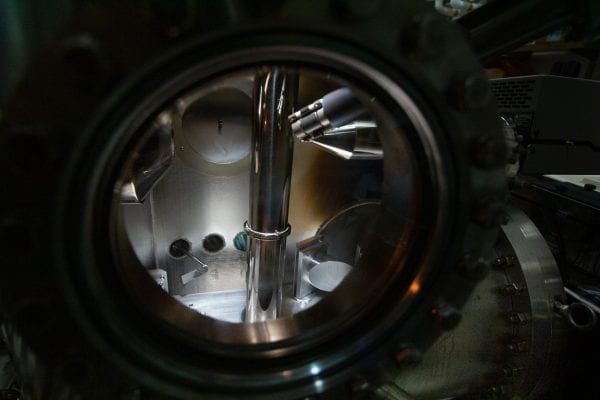

In order to carry out these experiments, Becca and Michelle used a highly specialized custom-built instrument in the Sibener group which allowed them to combine molecular beam techniques with time-resolved, in situ reflection absorption infrared spectroscopy (RAIRS) and King and Wells mass spectrometry techniques. This instrument features a central ultrahigh vacuum (UHV) chamber (10-10 Torr) in which icy films grown on a Au(111) substrates were mounted in a state-of-the-art helium-cooled sample manipulator. To investigate the structure, the icy surface was exposed to IR radiation and the reflected beam was analyzed with a liquid nitrogen cooled detector (RAIRS techniques). Connected to the UHV chamber is a triply differentially pumped molecular beamline, from which narrow, collimated beams of CH4 or 1% CH4 diluted in H2 were aimed at the ice film, with its incident energy set by resistively heating the beam nozzle. The probability of methane adsorption on the icy surface was quantified using the King and Wells technique in which a residual gas analyzer connected to the chamber used mass spectrometry to measure the quantity of methane ions reflected off of the ice surface over time.

A view into the chamber through a different porthole shows the optics for data collection and the connection to the beamline.

Technical and safety aspects

As described above, the instrument used in these studies is highly technical and requires experienced and educated students for its operation. Becca and Michelle walked the JRSI through the specialized instrumentation and touched on a few of the technical and safety considerations that were inherent in the successful completion of their experiments, including careful testing of thermocouples, frequent pump maintenance, gas mixing techniques, and group member training.

One aspect of the instrument in these experiments that Becca and Michelle carefully monitor is the thermocouple on the beam nozzle which is resistively heated. Due to the rigorous exclusion of oxygen and extremely high vacuum in this set-up, the primary concern with heating CH4 or CH4 in H2 is that accidental overheating could result in decomposition of the gasses within the chamber to a carbon based char. The temperature of the nozzle is measured by the attached thermocouple, which is rigorously tested to ensure proper readings. Long before experiments begin, Becca and Michelle remove the thermocouple from the instrument and test it out on the bench to make sure that the circuit is continuous. They then re-attach the thermocouple to the nozzle in the instrument and test the temperature reading again. They also ensure that the thermocouple doesn’t disengage from the nozzle when they apply heat or a jostling force. After the instrument is placed under vacuum, they test the temperature reading a third time. Once they begin the experiment, the standard procedure is to heat the apparatus stepwise up to the desired temperature. Using this experimental approach, they can confirm that the thermometry is working appropriately with only a small amount of applied power.

One of the most common maintenance procedures Becca and Michelle perform on their instrument is changing the oil in their diffusion pump. This pump allows them to reach very low pressures by compressing gasses using boiling oil vapor jets followed by ejection into mechanical pumps. Safety checks are in place to cut the power to the pump automatically if either the pressure gets too high or the water cooler attached to it stops working. In order to perform maintenance, Becca and Michelle turn off the pump and allow it to cool down to room temperature before carrying out any operations. Electrical hazards are safely dealt with by turning off all sources of electrical power to the pumps, including the electrical breakers, before any work is started. Once they are finished with any maintenance and before turning the pump back on, they check the resistances between different leads from the plugs to the heater components and compare the recorded values to those in the manual. “We do a lot of careful calibration to make sure it is hooked up the way it should be, and the resistance is appropriate before we turn it on” says Becca.

In carrying out these experiments, Becca and Michelle used gas tanks of pure methane and gas mixtures of 1% methane seeded in hydrogen as sources for their molecular beams. As with all flammable gasses, they used the appropriate regulators and made sure to store these gasses away from oxidizing gasses and electrical hazards. Although the gas mixtures used in this study were purchased from Airgas, the Sibener group now has their own state-of-the-art manifold for preparing custom gas mixtures. The system was built by Sibener group student Tim Grabnic and postdoctoral scholar Dr. Jacob Graham in a collaboration with other members of Sibener group, Airgas, and the UChicago Office of Research Safety. The Sibener group took extreme care in designing the manifold so that gasses could be safely mixed, taking precautions like using oil free pumps to exclude flammable materials from the surrounding area and using gas monitors to confirm the connections in the manifold are sealed. A meticulous SOP detailing allowed procedures is in place for those wishing to use the manifold. For example, “there are two different setups depending on what you need to mix, whether it is oxygen or flammable” explains Michelle. Becca and Michelle are now using this system for their next project, in which they are using a 5% oxygen in neon mixture.

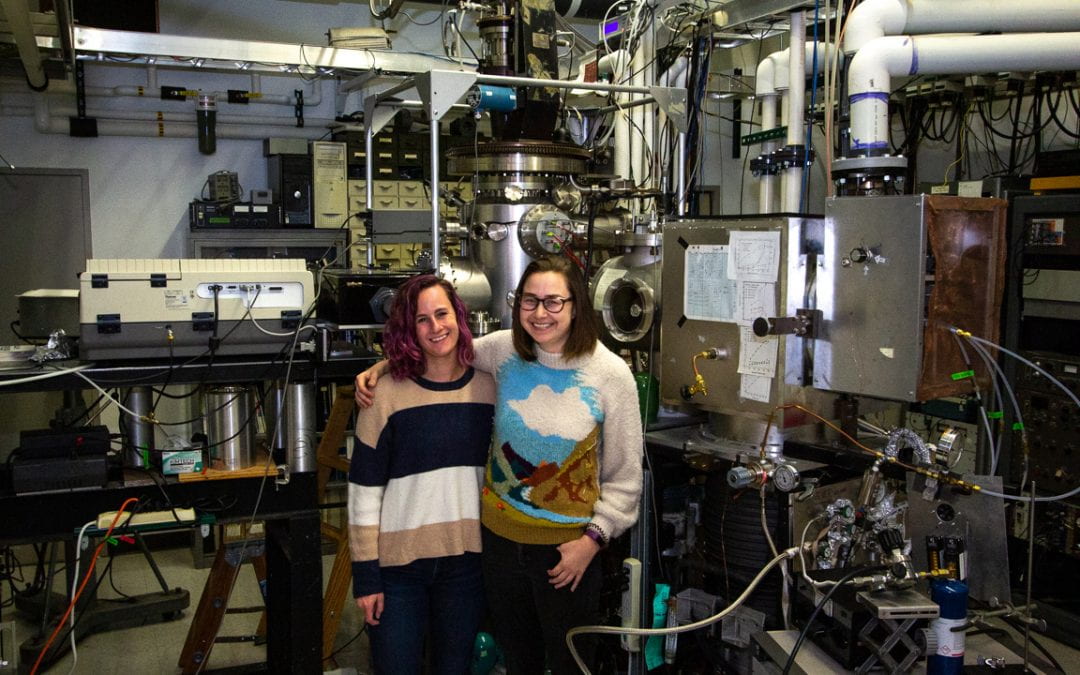

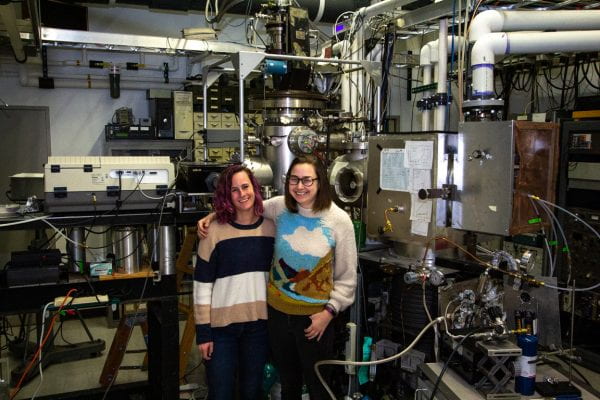

Graduate student researchers Becca (left) and Michelle (right) in front of the instrument used to collect data for their publication.

The instrument used by Becca and Michelle is one of multiple custom-built instruments in the Sibener group. With such a complex arsenal of custom-built instrumentation, the Sibener group utilizes multiple avenues to ensure knowledge transfer on safe and effective instrument use. When new students join, they are paired with a senior student who provides specific, hands on training, as was originally the case with Becca and Michelle’s partnership. Additionally, maintenance notebooks and manuals are all stored conveniently for reference. Lastly, Becca has curated a group wiki page wherein detailed instructions for routine procedures and maintenance for each instrument are compiled, kept, and updated throughout the years. This wiki serves as a reference for when a group member wants to develop a new procedure, and as a starting place for new students. Instead of “reinventing the wheel,” as Becca says, group members can look to see if a similar procedure has been done with another instrument.

In their paper, Becca and Michelle shed new light on the adsorption of methane to icy surfaces and emphasize that surface structure can be an important factor to consider when modeling gas/surface interactions. These new findings are a result of their specific knowledge of surface chemistry and their technical expertise in designing careful experiments on custom built instruments.

[1] “Sticking Probability of High-Energy Methane on Crystalline, Amorphous, and Porous-Amorphous Ice Films”

Rebecca S. Thompson, Michelle R. Brann, and S. J. Sibener

J. Phys. Chem. C 123,17855-17863 (2019) DOI: 10.1021/acs.jpcc.9b03900